Warping / Sizing

In house warping & sizing facility to ensure better & consistent fabric quality from looms.

- Manufacturer - Karl Mayer

- Type of machine- WD/2400

Warping Machine

- Manufacturer KARL MAYER Textile machine AG-9240 UZWILL Switzerland

Sizing Machine

Air Jet Looms

We believe in continuously balancing & modernization of our plant, keeping this in mind, we have now added in our weaving set-up brand new Air jet looms.

| Looms: | Toyota Jet 810 |

| Size: | no of looms |

| 190cm: | 36 |

| 280cm: | 24 |

| 340cm: | 54(TPPET) |

| 340cm: | 06(dobby) |

| Total: | 120.00 |

Weaving

Our weaving section comprises of 102 shuttle less looms in house & 500 shuttle less looms in our sister concerns in widths 130’’ & 153’’ with the total capacity to produce 24 million meters of fabric/year.

600 Auto looms are on contract with capacity to produce about 14 million meters of fabric/year.

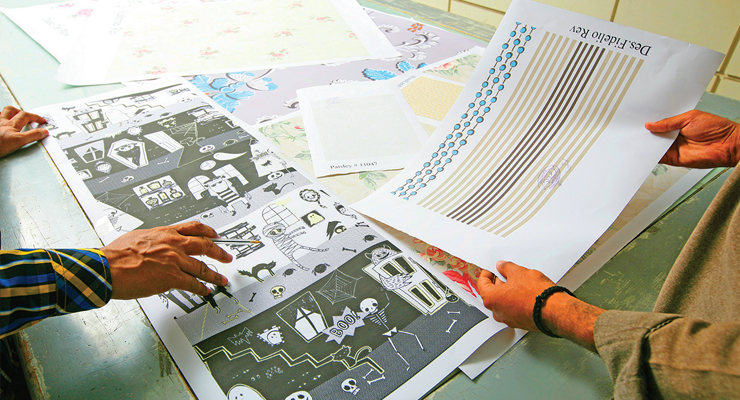

Design Development

Creation is a product of human imagination, which hold a core position in designing & printing. The use of a variety of softwares has enabled us to communicate the concept of design to individual customers for their selection & approval.

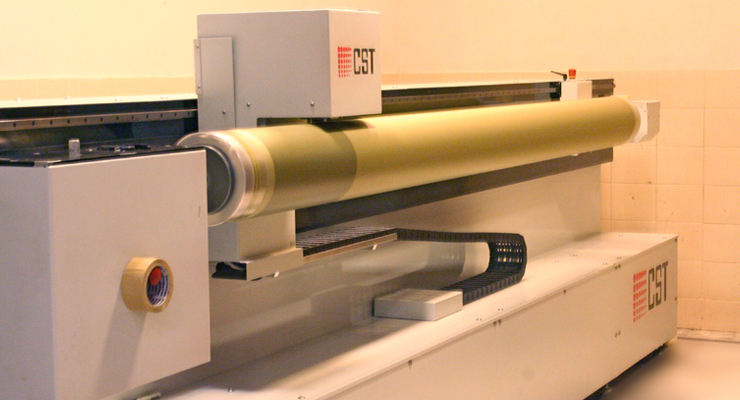

Engraving

In order to assure Perfection in design. we have a

state of art equipment listed below in our CAD

/ CAM equipped design studio.

Processing

1 Singeing Osthoff - Germany

Working width: 320cms

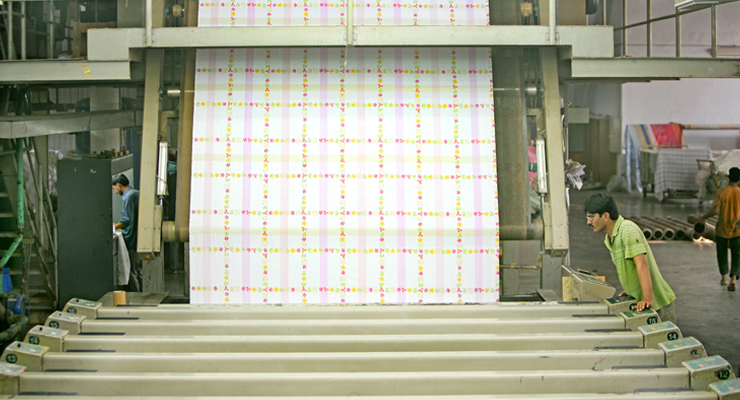

Printing

The rotary printing facility at M.K. sons (pvt.) Ltd.

processes the most fascinating designs with high precision & accuracy in pigment & reactive range.

- (2) Reggiani – Italian Made Rotary printing machines.

- Digital Printing Alpha 330

- Pass 300X600 dpi, 460 lm 1.470 m2/h

- Printing width 3000 mm

Dyeing

We provide quality dyed fabrics to our valuable customers /

leading home textile brands. In order to ensure excellent dyeing

standards, we use high quality grey fabric and dyeing material

depending upon the specification.

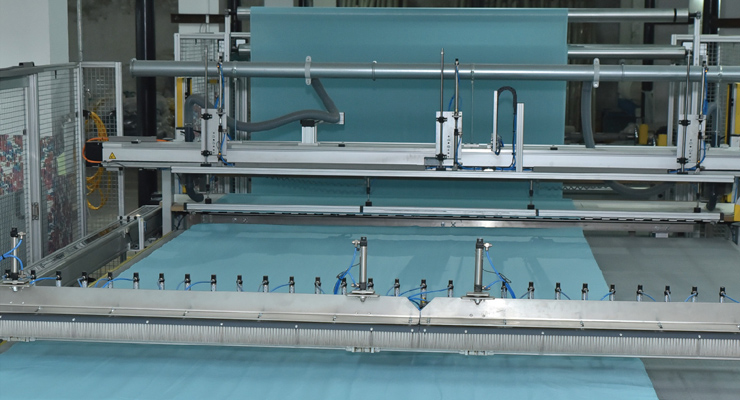

Finishing

A part from appearance, the pleasant feel adds value to processed fabric & we take care of this aspect by using stringent control while finishing the fabric.

- (7) Stenters-Monforts Germany

- Working width : 320cms, with "Mahlo" weft straighter both on entery & Exit

to control bowing. - BENNINGER - the Swiss made machine for pretreatment has facility to desize

washing and bleaching separately if needed.

Laboratory

We have fully equipped lab to conduct tests as per customers desired standards to ensure our products quality.

- Titan (Tensile strength tester) by JamesH Heal England.

- Spray Tester (Water repellency test) by JamesH Heal England.

- NU-Martindale Pilling & Abrasion Tester by JamesH Heal England.

Embroidery

Newly added gem in the form of fully computerized 20 heads “BARUDAN” from (Japan) high speed embroidery machine capable to make designs in 9 colors. Maximum Speed: 1000 rpm.

Stitching

Area expanded up to 200,000 sq. feet with an array of 500 machines

Including switch track, our capacity is to cut and sew around 1.5 million

meters of fabric per month.

SmartMRT Unit Production Hanger System

We have a highly advanced computerized system that tracks and records every stage of production in real-time, workflow is made simple, neat and effortless.

Quilting

Fully equipped unit with 6 computerized single needle quilting machines.

Production capacity: 1000 BIAB/day

Multi Needle Quilting

A step forward in providing value added quilted articles; fully computerized 2 multi-needle

quilting machines are inducted in our production setup.

- Working Width: 305 cm.

- No. of Needles: 240

Garment Washing

We have facility of sustainable denim washing system with sate of the art machinery ‘YILMAK’ with the capacity of 2 tons per day that create wash look appearance, seems the new touch of fashion, also reduce size materials that imports soft hand feels.